Matchmaker CNC are proud to be the UK's authorised supplier of Mitsubishi Machine Tools.

Below are two of our most popular Mitsubishi Machining Centres. For further details of these or any other machines in the Mitsubishi range, please call Matchmaker CNC on 01372 844999.

µV5 Micro Milling Machine

Newest Addition to the µV (micro V) Series Allows for Machining of Large Workpieces with Micrometer-Level Precision

The µV5 has a bigger working surface table and wider process stroke than the current µV1, allowing for high-efficiency machining with micrometer-level (1/1,000 mm) precision for large products or those that require fine milling using small diameter tools, such as moulds for car optical components.

The µV5 meets demand for a wide range of applications such as precision automotive parts, large-scale moulds for display casings and other products, separators (the main component of fuel cells), and shaping blades for rotating machines.

Large Precision Machine MVR FX Series

Zero Step, Zero Form Error and Zero Hand Finishing

MVR・Fχ achieves high quality surface without any surface steps and increases the productivity by reducing the need of hand finishing.

MVR・Fχ reproduces shapes of machining data precisely and can manufacture the Die-Mold which accurately reflects the designer’s intention. In addition, customers can accumulate their technical data and database their know-how by combining 3D measuring system and MVR・Fχ. Therefore, MVR・Fχ reduces trial manufacture, which then leads to shorter delivery time and reduction of man-hours.

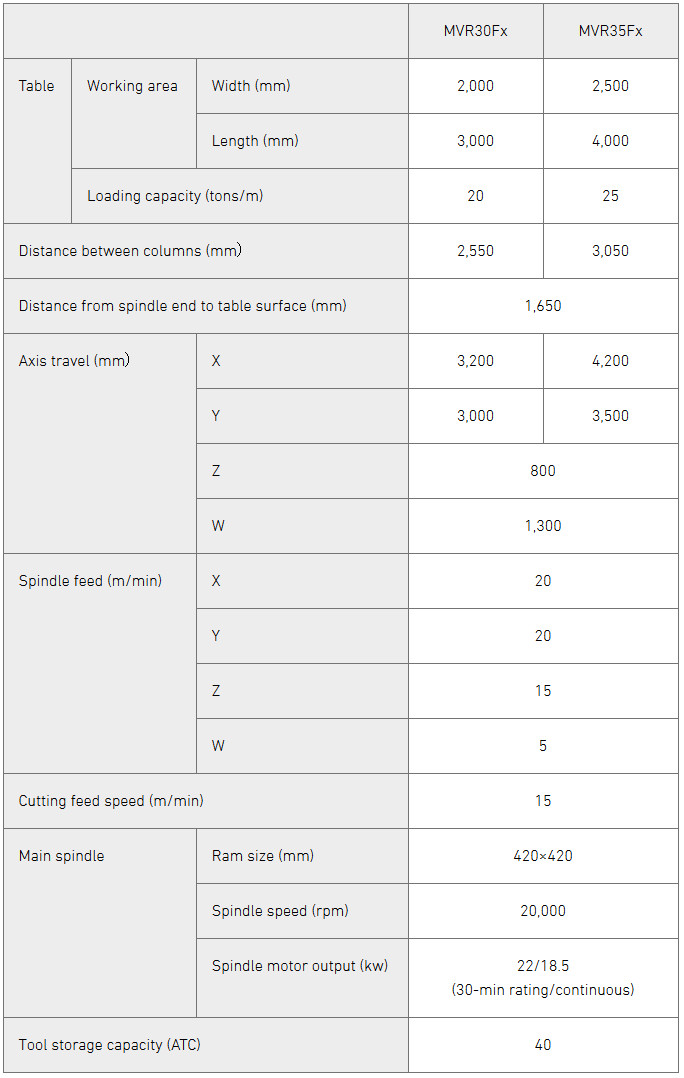

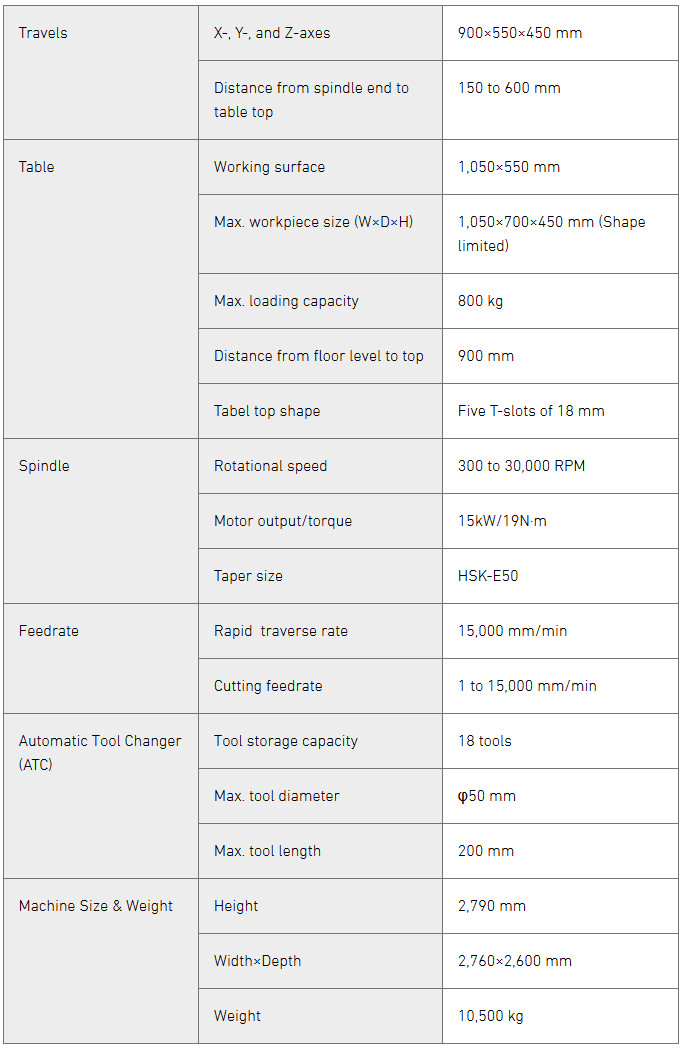

Main Specifications of the μV5 Micro Milling Machine

Main Specifications of the MVR FX Series